Views: 289 Author: Lily Publish Time: 2025-12-01 Origin: Site

Content Menu

● 1. Introduction to Automatic Spray Painting Machines

>> Key Features of Automatic Spray Painting Machines

● 2. Qingdao Guangyutai Machinery Co., Ltd.

● 3. Advantages of Automatic Spray Painting Machines

>> 3.1 Consistency and Quality

● 4. Key Technologies in Automatic Spray Painting Machines

>> 4.1 Electrostatic Spray Technology

>> 4.2 Advanced Nozzle Designs

>> 4.3 Programmable Control Systems

● 5. Applications of Automatic Spray Painting Machines

>> 5.2 Furniture Manufacturing

● 6. Future Trends in Automatic Spray Painting Machines

In the realm of industrial manufacturing, the automatic spray painting machine has become an essential tool for achieving high-quality finishes efficiently. These machines are designed to automate the painting process, ensuring consistency, precision, and speed that manual methods cannot match. This article will delve into what makes an automatic spray painting machine stand out, with a particular focus on Qingdao Guangyutai Machinery Co., Ltd., a leading manufacturer in this field.

Automatic spray painting machines are sophisticated devices that apply paint or coatings to surfaces using automated processes. They are widely used in various industries, including automotive, furniture, electronics, and aerospace. The primary advantage of these machines is their ability to deliver consistent results while significantly reducing labor costs and material waste.

- Precision Control: Automatic spray painting machines utilize advanced technology to control the spray pattern, flow rate, and pressure, ensuring a uniform application of paint.

- High Efficiency: These machines can operate continuously, allowing for higher production rates compared to manual painting methods.

- Reduced Waste: By optimizing the amount of paint used and minimizing overspray, automatic machines help reduce material costs and environmental impact.

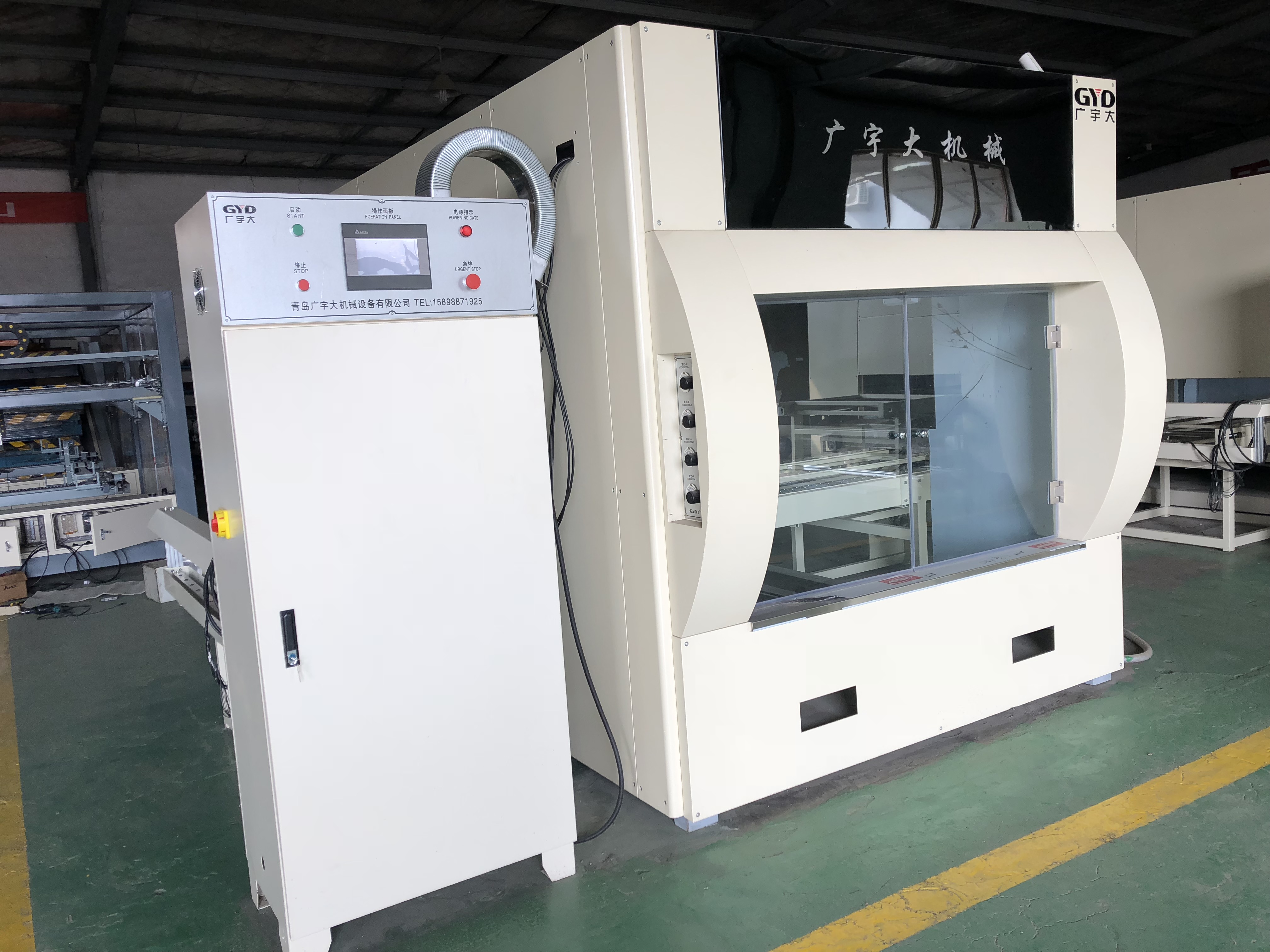

Qingdao Guangyutai Machinery Co., Ltd. is at the forefront of the automatic spray painting machine industry. With a commitment to innovation and quality, Guangyutai offers a range of machines that cater to various industrial needs.

- Innovative Technology: Guangyutai integrates the latest technology into their machines, ensuring high precision and efficiency.

- Customization Options: Their machines can be tailored to meet specific customer requirements, making them versatile for different applications.

- Robust Performance: Built to withstand the demands of industrial environments, Guangyutai machines are known for their durability and reliability.

One of the most significant advantages of automatic spray painting machines is their ability to deliver consistent quality. Unlike manual methods, which can vary based on the operator's skill and technique, automatic machines ensure that each application is uniform. This consistency is crucial in industries where quality control is paramount.

Automatic spray painting machines can operate at a much faster rate than manual painting. They can handle large volumes of work without the need for breaks, leading to increased productivity. This efficiency is particularly beneficial in high-demand environments where time is of the essence.

While the initial investment in an automatic spray painting machine may be higher than manual methods, the long-term savings are significant. These machines reduce labor costs, minimize material waste, and decrease the need for rework due to inconsistent finishes. Over time, businesses can see a substantial return on investment.

Automating the painting process also enhances safety in the workplace. By reducing the need for human operators in potentially hazardous environments, automatic spray painting machines help minimize exposure to toxic fumes and chemicals. This is especially important when using solvent-based coatings.

Electrostatic spray technology is a game-changer in the automatic spray painting industry. This technology uses an electric charge to attract paint particles to the surface being coated, resulting in a more efficient application with less overspray. This not only saves material but also ensures a more even finish.

The design of the spray nozzle plays a crucial role in the performance of an automatic spray painting machine. Advanced nozzles are engineered to optimize atomization, allowing for finer paint droplets that provide better coverage and a smoother finish. Adjustable spray patterns further enhance the versatility of these machines.

Modern automatic spray painting machines come equipped with programmable control systems that allow operators to set specific parameters for each job. This flexibility enables quick adjustments for different paint types, colors, and surface materials, making it easier to switch between projects without significant downtime.

In the automotive industry, automatic spray painting machines are essential for achieving high-quality finishes on vehicles. These machines can handle large surfaces and complex shapes, ensuring that every part of the vehicle is coated evenly.

Furniture manufacturers benefit from automatic spray painting machines by achieving consistent finishes on various materials, including wood, metal, and plastic. The ability to customize spray patterns and colors allows for creative designs while maintaining efficiency.

In the electronics sector, automatic spray painting machines are used to apply protective coatings to circuit boards and other components. These coatings help protect against moisture, dust, and other environmental factors that could affect performance.

The aerospace industry requires the highest standards of quality and precision. Automatic spray painting machines are used to apply coatings that meet stringent safety and performance standards, ensuring that every component is protected and visually appealing.

As technology continues to evolve, so too do automatic spray painting machines. Future trends include:

- Increased Automation: The integration of AI and machine learning will lead to even more efficient and precise painting processes.

- Sustainability: There will be a greater focus on environmentally friendly coatings and processes that reduce waste and energy consumption.

- Smart Technology: The use of IoT (Internet of Things) will enable machines to communicate with each other, optimizing production lines and reducing downtime.

Automatic spray painting machines are transforming the manufacturing landscape by providing consistent, high-quality finishes while enhancing productivity and safety. Qingdao Guangyutai Machinery Co., Ltd. leads the way in this industry, offering innovative solutions that meet the diverse needs of various sectors. As technology advances, the capabilities of these machines will only continue to improve, making them an indispensable tool for manufacturers worldwide.

1. **What is an automatic spray painting machine?

- An automatic spray painting machine is a device that automates the process of applying paint or coatings to surfaces, ensuring consistent and efficient application.

2. **What are the benefits of using an automatic spray painting machine?

- Benefits include increased efficiency, reduced labor costs, consistent quality, and minimized material waste.

3. **How does electrostatic spray technology work?

- Electrostatic spray technology uses an electric charge to attract paint particles to the surface being coated, resulting in a more efficient application with less overspray.

4. **Can automatic spray painting machines handle different types of coatings?

- Yes, many machines are designed to work with various coatings, including water-based, solvent-based, and powder coatings.

5. **What industries benefit from automatic spray painting machines?

- Industries such as automotive, furniture manufacturing, electronics, and aerospace all benefit from the use of automatic spray painting machines.

Top 5 Automatic Spray Painting Machines: Which One Is Right for You?

Wood Door Planer Sanding Machine: Ultimate Guide to Efficient Door Shaping and Finishing

Mastering the Art of Paint Spraying Cabinet Doors: A Comprehensive Guide for a Professional Finish

The Future of Industrial Coatings: Comprehensive Guide to Automatic Spray Painter Systems

Revolutionizing Surface Preparation: The Ultimate Guide to Automatic Paint Stripping Machines

Automatic Paint Brush Wooden Handle Making Machine: Revolutionizing Paint Brush Production

Wholesale Wire Brush Sanding Machines: A Comprehensive Guide